Machinery CE / UKCA Audit

Purchasing a machine with a CE or UKCA Mark is no guarantee that the machine will be fully compliant and safe. We often inspect new machinery under PUWER and record a number of non-compliances.

We recommend that a machinery CE / UKCA Audit is carried out on new machinery before it leaves the manufacturer, so that any non-compliances can be addressed before the machinery is shipped to your facilities. We often accompany our customers during the Factory Acceptance Test (FAT) to carryout a CE/UKCA Audit.

Following the CE/UKCA Audit, we will discuss our findings with the supplier and customer in order that non-compliances can be addressed prior to shipping.

Why CE / UKCA Audit?

Once a machine arrives at you factory, the priority is to complete installation and commissioning in order that the new machine can start production.

If no CE / UKCA audit is carried, we see a higher number of PUWER non-compliances that could delay production or stay on your snagging list for years, as no-one wants to stop a machine that has just started production.

Machinery Safety Support

Safemach also support customers with their new machinery safety and compliance.

We will review your Request for Quotation (RFQ) with regards to safety and compliance before it is sent out to potential suppliers to ensure the relevant safety and compliance topics are included.

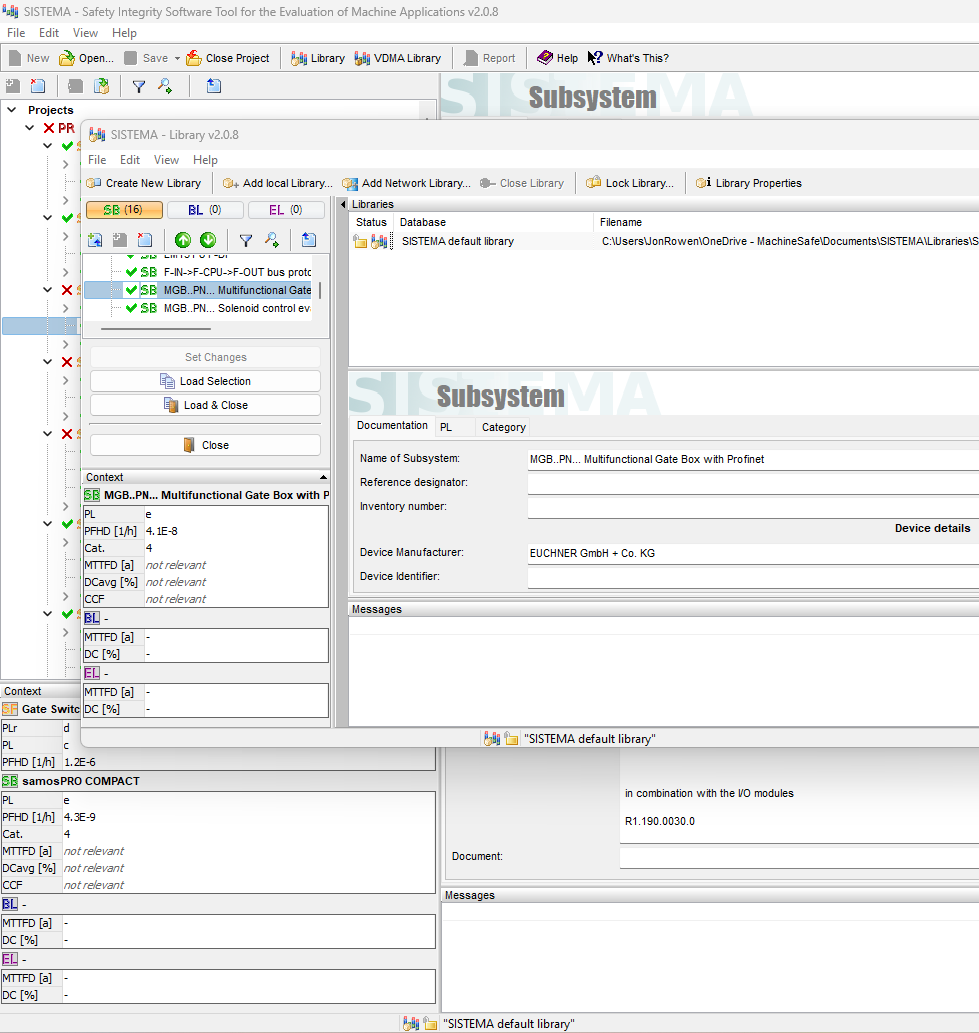

We can also attend your project meetings acting as your safety and compliance specialist to discuss safety and compliance topics, review safety related documentation such as machinery design risk assessments, safety requirement specification, Sistema, etc.

What Next?

If you are planning or have purchased new machinery, then please contact Safemach to see how we can support you in ensuring your new machinery is safe and compliant.